New polyurea coatings being tested by the U.S. Naval Research Laboratory can create a rubber surface that not only stops corrosion but improves the ballistic protection of armored amphibious assault vehicles.

The reported advance could provide a quantum leap in shielding the U.S. Marine Corps’ AAV fleet from two critical threats at once, developers say.

The U.S. Marine Corps’ mighty Amphibious Assault Vehicles (AAVs) remain vulnerable to corrosion when their paint cracks under intense duty. New elastomeric coatings may change that.

They seem to have solved the corrosion problem. And with a negligible increase in weight, they also provided better ballistic protection and a higher payload capacity.

|

| U.S. Naval Research Laboratory/Jamie Hartman |

| Drs. Ray Gamache (left) and Mike Roland of the U.S. Naval Research Laboratory are testing polyurea coatings on steel pieces of amphibious assault vehicle armor in heated, oxygenated sea water. |

Battling Brittleness

AAVs, introduced in 1972, have been bolted with armor since the 1990s. The armor protects against ballistics but is easily eroded under intense use and constant exposure to saltwater.

Some types of rubber provide corrosion protection—and potentially better ballistic protection—for amphibious assault vehicles (AAVs), Naval researchers have found.

Conventional paints become brittle and crack under such conditions, allowing corrosion to take hold.

You’ve got rubber, steel—and these things are thermally expanding and contracting differently. In addition to which, AAVs aren’t driven like expensive Volvos; they’re banging into stuff—and now you’ve got a way for water ingress.

Polyureas, on the other hand, can stretch instead of cracking. The rubbery surface not only prevents entry points for water and corrosion but can even absorb kinetic energy from bullets, slowing them down, the researchers say.

If slowed enough, Roland says, the bullet won’t penetrate the steel plate below.

Field Testing

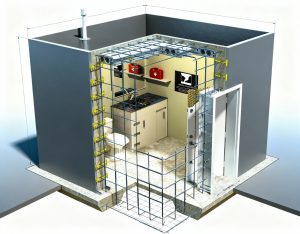

The U.S. Naval Research Laboratory are testing polyurea coatings on steel pieces of amphibious assault vehicle armor is heated, oxygenated seawater.

Working at NRL’s facility in Key West, FL, the researchers are immersing bent pieces of steel (to simulate banged-up tank surfaces) in troughs and aquariums full of seawater—heated to accelerate corrosion and bubbled with air to add plenty of oxygen.

Five coatings are being tested:

- Two paints.

- A polyurea that NRL has been using in other armor applications.

- An unidentified private company developed two polyureas.

The paints crack when the pieces are bent; however the elastomeric polyureas don’t.

Companies are helping the Marines develop optimal maintenance for AAVs already in service.

They quantified how much they’re going to lose, in ballistic performance, with the corrosion. This will guide the Marine Corps when they need to replace or repair the armor, saving a lot of money.

‘Best of Both Worlds’

Polyureas owe their toughness to hydrogen bonds.

The technology isn’t new, but after examining elastomer applications for armor for a generation, coating scientists have a better grasp of which rubbers work and which ones don’t.

The elastomers can stretch to 10 times their original length, but the force it takes to do that is enormous—so you get toughness, the best of both worlds.