Latest Articles

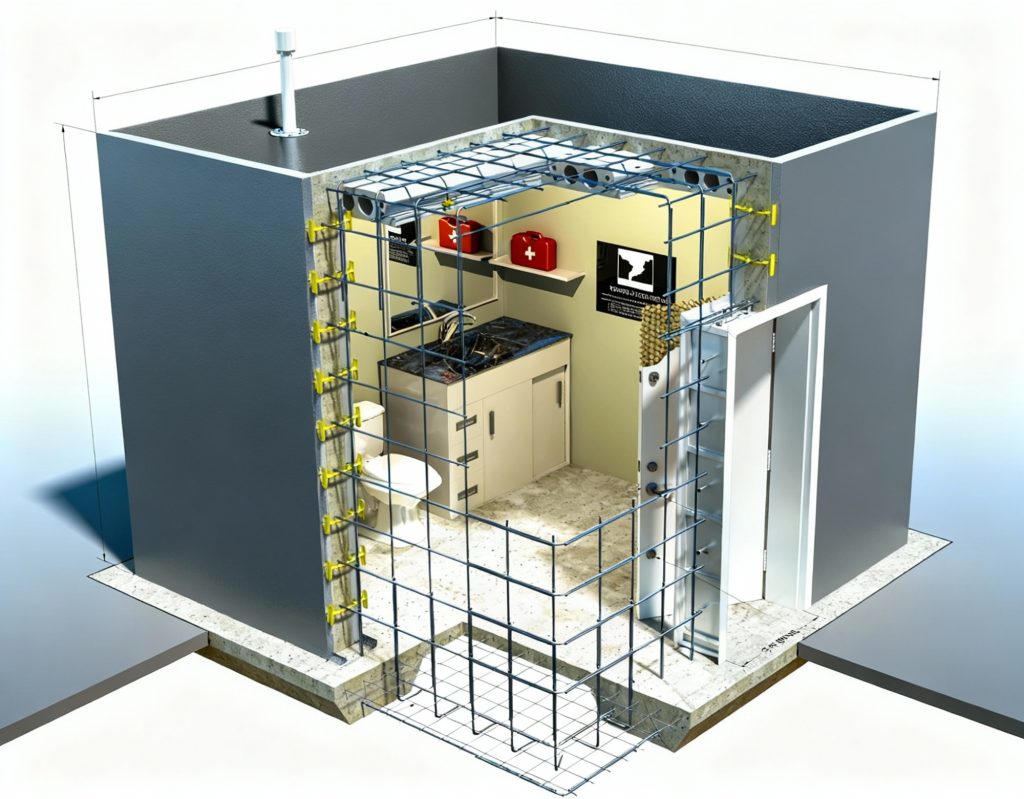

Safe Room Coatings and the Case for Seamless Protection

A safe room is designed to provide security when everything outside of it becomes uncertain.…

Dunnage Coatings and Their Role in Cargo Reliability

The transport of goods depends on more than trucks, ships, or containers. Hidden beneath the…

Bridge Coatings: Extending the Life of Critical Infrastructure

Bridges remain some of the most vital components of modern infrastructure, linking communities and enabling…

A PRACTICAL GUIDE TO SPECIFYING POLYUREA COATINGS FOR FLOODWALLS AND LEVEES

Riverine and coastal floods now arrive faster and hit harder, straining levees, floodwalls, sluice gates,…

ELEVATING FLAT-ROOF WATERPROOFING WITH POLYUREA SEAMLESS SECURITY

Polyurea is no longer a newcomer for flat roof waterproofing applications, yet many stakeholders still…

Cistern Liner Coating Applications and the Challenge of Uneven Substrate Expansion

Understanding Expansion Behavior in Large-Scale Cisterns In most cistern liner conversations, the focus tends to…

How to Start a Successful Polyurea Deck Protection Business

The process of beginning a business operation can generate both financial gain and personal fulfillment. …

Molecules To Membranes: How Polyurea Coatings Protect Tanks Better

Polyurea coatings have rapidly gained traction as a superior solution for protecting industrial tanks and…

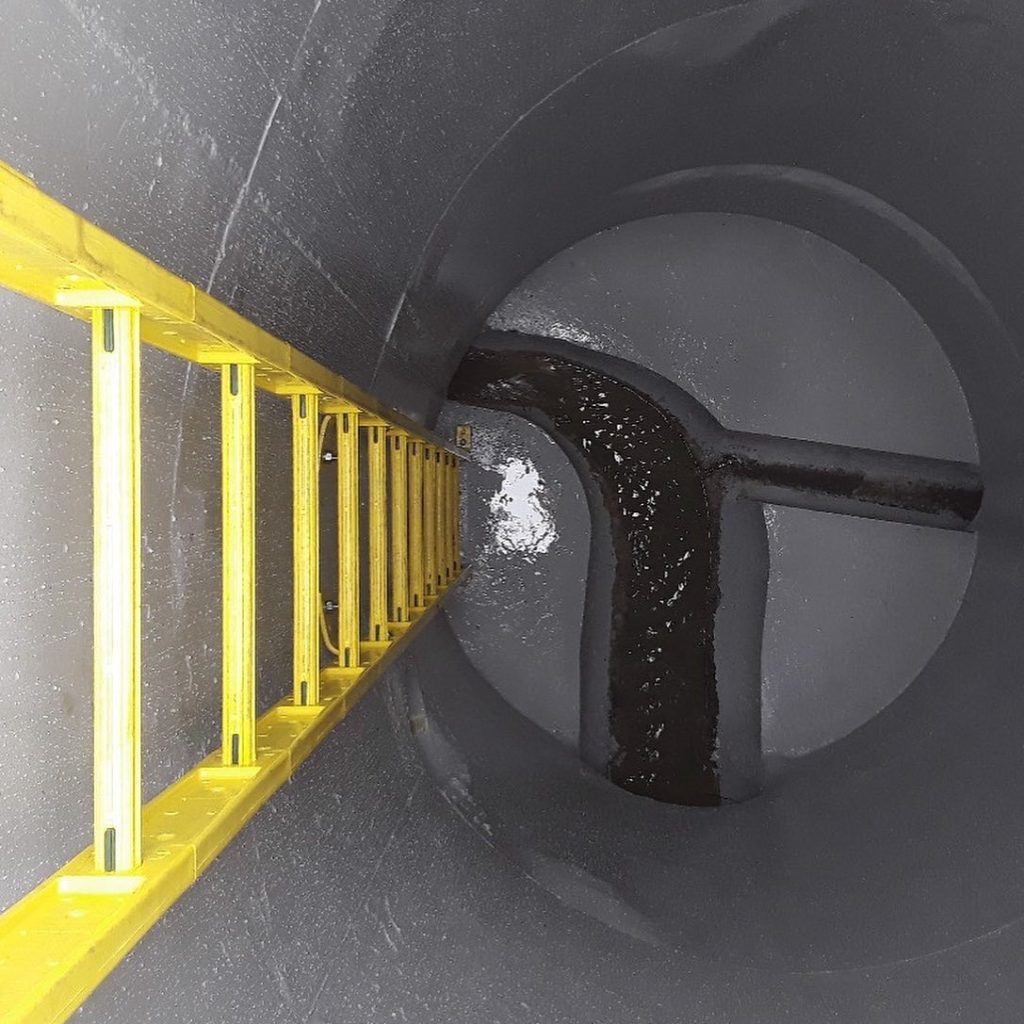

Why Municipalities Should Apply Manhole Coatings In House

INDEPENDENCE HAS NEVER BEEN EASIER Municipalities, busy as they are, have often sought outside help…