Choosing the best equipment is vital to a company that operates in spraying material for insulation and coating projects. Carrying out a task effectively often depends upon the equipment or tool it is performed with, so it is important to understand the different types of spray machinery to carry out a task properly.

Coating equipment and spray machines are not equal in their ability to run with certain materials, as they require different pressures to use. Most high-pressure ranked equipment could be interchangeable no matter whether it is used for spraying polyurea or foam, however, lower pressure machines are frequently just used for spray foam. This is since the proper product circulation for coatings requires to be at or above 1850– 3500 psi, while foam application can be performed by machines in 800 to 2000 psi ranges. The caveat here is that lower pressure machines are suitable for spray foam only under the condition of not using long hoses. Those require higher pressure to disperse the material effectively.

Pneumatic and Air-Driven Machines

Air-driven or pneumatic equipment has remained in use for over 60 years, though the technology has come a long way in terms of its general efficiency. The technology behind these machines is based upon a fundamental two-component mix: two pumps operated by an air motor operating within a particular pressure ratio. The psi score of a machine correlates to just how much material it can distribute in fluid pressure. So if the pressure ratio is 25:1, the machine can deliver 25 psi of fluid pressure for every pound of air pressure applied.

As long as the host is big enough to dispense the required product, pneumatic systems will regularly distribute the application. It is not a surprise then that this innovation has actually been around for years and is extremely reliable. Still, the clear downside is that it does not allow the pressure to be sufficiently kept track of, burdening the operator with the task of seeing the foam for correct circulation and application.

For companies simply beginning, pneumatic equipment is typically the go-to option due to its relative simpleness and lower rate point. Nevertheless, as organization gets and bigger jobs start to need higher output machinery.

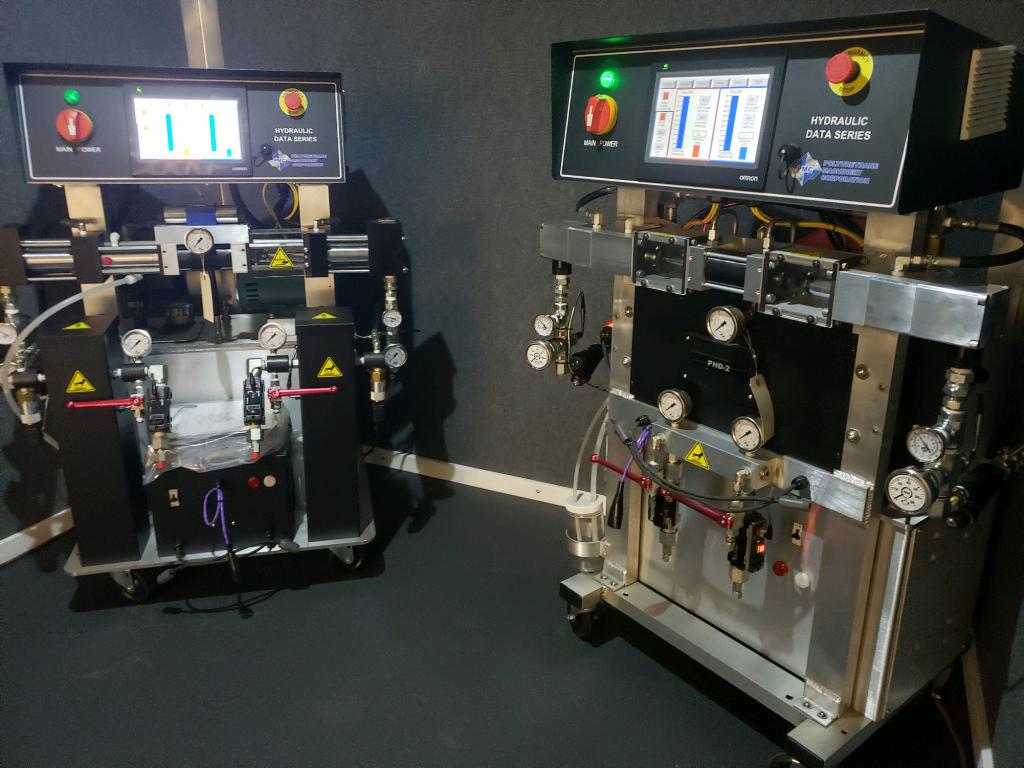

Hydraulic Machines

Presented in the 1970s, hydraulic equipment uses hydraulic power to run chemical proportioning pumps and is typically used to apply polyurea coatings and dual-component foam. Some of the systems even consist of a valve that permits the instructions of the sprayer to alter. The fast pump changeover is the machine’s most appealing quality, resulting in minimal pressure loss when the instructions changeover happens.

As the chemicals utilized in spray foam need to mix prior to application, the hydraulic application enables better monitoring methods to guarantee that the mix of chemicals is consistent and proportional. If the system spots improper mixing, it closes down immediately to prevent bad product circulation, allowing the operator to deal with the problem rather than use the poor product.

Polyurea and foam chemicals require a heating point of anywhere between 100 and 180 degrees Fahrenheit. Main heating units heat the chemicals to necessary temperatures, and heated hose pipes maintain the temperature set indicate guarantee that good quality foam is included through these higher-quality hydraulic systems.

When it pertains to large-area applications, such as coating wide roofs, using a hydraulic machine to spray foam is specifically reliable, allowing for great heat efficiency and optimal output.

Electric Machines

When high throughput is required for a coating or spray foam application job, electric spray systems offer a piece de resistance value, making them perfect for professionals trying to find polyurea equipment for sale.

Electric machines are beneficial in maintaining constant pressure as the spray or coating applicator is activated and keep proper stall pressure levels when the machine is on however not functional.

Motor control tech ensures that the two mixing pumps keep the very same quantity of fluid pressure and manage the motor’s electrical existing. The pumps and applicator orifices are comparable in size, so the two pump pressures need to be close to the exact same for the proportioner to achieve a 1:1 chemical ratio. Modern equipment will right away shut down if the pump pressures start to fall out of sync and lose balance, stopping the user from spraying bad foam or coating, with an error informing the user about the cause of the shutdown.

The heating aspect of electric machines is also highly advantageous. Electric spray foam systems heat the chemicals to their essential heating point with big main heating systems to be practical. While the majority of specialists depend on pipes to keep the heated temperature of the item as it is being sprayed, cooler temperatures can cool off insulated tubes, causing them to require to be warmed up prior to in fact actively having the retention capability. If the machines have been off for an extended duration, by the time the tubes are at a point where they can maintain the needed heat temperature levels, a considerable quantity of time would have been wasted.

Electric systems are not just dependable but, with appropriate maintenance, can have fantastic longevity. Obviously, they are an investment, and their upkeep will sustain extra expenses, however, it will be much better than buying a brand new tool. Such systems have been understood to last anywhere from 15 to 25 years.

Conclusion

If you are searching for a polyurea spray machine for sale, consider checking out the PMC polyurea machine and Graco polyurea machine. For spray foam insulation, think about the Graco foam machine or PMC foam machine. Whether you are looking for brand-new or pre-owned polyurea spray equipment for sale, you can discover lots of choices suitable for all kinds of tasks here.