Cities across the country are facing mounting challenges in maintaining aging infrastructure. From deteriorating bridges to leaky wastewater treatment plants, municipal leaders are increasingly looking for cost-effective and durable solutions. In recent years, many municipalities have begun investing in their own polyurea spray rigs, allowing them to take infrastructure maintenance into their own hands rather than relying solely on outside contractors. This shift is revolutionizing public works, offering cities a more efficient and long-term approach to maintaining critical assets.

Why Municipalities Are Investing in Polyurea Spray Rigs

Municipal budgets are stretched thin, and maintenance costs are rising. Historically, local governments have had to bid out infrastructure repairs to third-party contractors, often resulting in high costs and project delays. However, the ability to apply spray-applied polyurea coatings in-house allows for more immediate repairs, lower labor costs, and reduced dependence on external service providers.

Polyurea has become an attractive choice because of its rapid curing time, durability, and ability to bond to various substrates. With proper training, municipal maintenance teams can apply polyurea coatings in-house, reducing overall maintenance expenses and extending the life of infrastructure components.

Key Uses of Polyurea Spray Rigs in Municipal Infrastructure

Municipalities have discovered that polyurea spray rigs are highly versatile tools that can be used across multiple departments. Some of the most common applications include:

1. Water and Wastewater Infrastructure

Cities and counties must ensure that water treatment plants, reservoirs, and sewer systems remain watertight and corrosion-resistant. Polyurea is widely used to coat concrete basins, pipelines, and manholes to prevent leaks, reduce chemical corrosion, and increase structural longevity. Municipalities with their own spray rigs can quickly apply coatings without waiting for outside contractors, ensuring compliance with environmental regulations and reducing the risk of costly infrastructure failures.

2. Bridge and Roadway Protection

Bridges and overpasses suffer from constant exposure to traffic, weather, and de-icing chemicals. Spray-applied polyurea can protect bridge decks and expansion joints from water intrusion and wear, preventing costly structural deterioration. By having spray rigs on hand, municipal crews can perform preventative maintenance rather than reacting to structural failures.

3. Parking Garages and Sidewalk Repairs

Public parking structures experience significant wear and tear from vehicle traffic and weather conditions. Polyurea coatings help create skid-resistant, waterproof surfaces that prolong the life of parking decks and sidewalks. Instead of outsourcing these projects, municipalities that own polyurea spray rigs can maintain these structures year-round.

4. Stormwater Management and Drainage Systems

Many cities are struggling with stormwater management, especially in flood-prone areas. Polyurea coatings can waterproof drainage channels, culverts, and stormwater basins, ensuring they remain intact during heavy rain events. The ability to reapply coatings on-site whenever needed helps municipalities keep drainage systems functional without the added cost of external contractors.

5. Recreational and Public Facilities

Parks and recreational areas require maintenance to keep surfaces safe and weather-resistant. Municipalities are now using polyurea spray rigs to coat playground equipment, skate parks, splash pads, and sports courts. These coatings provide slip resistance, UV stability, and impact protection, ensuring long-lasting recreational facilities for the community.

6. Vehicle and Equipment Protection

Public works departments manage fleets of vehicles, from garbage trucks to snowplows. Municipalities are using polyurea coatings to protect these vehicles from corrosion, impact damage, and abrasion. The ability to spray polyurea in-house means maintenance crews can extend the lifespan of their equipment while reducing costs on replacement parts and repairs.

Challenges and Considerations

While the benefits of in-house polyurea application are substantial, municipalities must also consider the training and safety requirements that come with using spray rigs. Applying polyurea requires specialized knowledge of proportioning units, spray techniques, and substrate preparation. Many cities are investing in training programs to ensure their crews can safely and effectively apply coatings.

Additionally, municipalities must ensure they comply with environmental and workplace safety regulations. Proper ventilation, protective equipment, and waste disposal methods are essential to maintaining a safe working environment when using spray-applied coatings.

The Future of In-House Infrastructure Maintenance

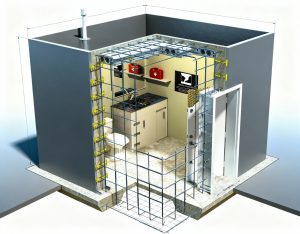

As more municipalities recognize the cost savings and efficiency of using polyurea coatings for infrastructure maintenance, the trend of investing in spray rigs will likely continue to grow. Advances in mobile spray rig technology are making it easier for cities to deploy polyurea coatings in remote and hard-to-reach areas. This shift allows for greater autonomy, faster response times, and a proactive approach to infrastructure management.

With the ability to apply long-lasting protective coatings on demand, municipalities are reducing repair cycles and enhancing the durability of public infrastructure. By embracing polyurea technology, cities are not only saving money but also ensuring the longevity and safety of critical assets that serve their communities for decades to come.