The transport of goods depends on more than trucks, ships, or containers. Hidden beneath the visible systems lies the dunnage, the blocks, cradles, racks, and supports that hold cargo steady. Without it, even the most secure container would allow goods to shift, scrape, or collide. Dunnage absorbs the stress of motion, resists vibration, and distributes weight. Yet dunnage itself carries the burden of constant wear, and when left unprotected, it fails faster than it should. The answer lies not in replacing it more often, but in shielding it with coatings designed to endure the punishment of daily use.

Why dunnage is more vulnerable than it seems

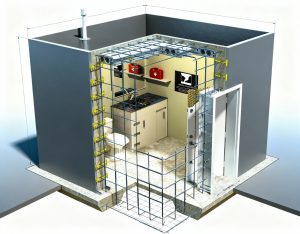

At first glance, dunnage looks rugged. Heavy steel frames, dense wood blocks, or composite supports appear strong enough to outlast the cargo they protect. The reality is different. Each time a forklift pushes against a rack, each time a chain is tightened, each time a load vibrates across a long highway, the surface of the dunnage suffers. Scrapes turn into gouges, bare metal rusts, wood swells with moisture, and plastics grow brittle under ultraviolet exposure. Over months and years, the cycle of loading and unloading weakens the very equipment meant to secure the load.

This is more than a maintenance inconvenience. Damaged dunnage compromises stability, posing a risk to both the cargo and the workers handling it. Repairing or replacing it takes time, and in logistics, delays are costly. For companies focused on efficiency, protecting the dunnage itself becomes as important as protecting the products it carries.

How coatings extend durability

Protective coatings address this problem at the surface level, where wear begins. A layer of specialized material creates a barrier that resists abrasion, seals out moisture, and shields against chemicals. The base material—steel, wood, or plastic—remains intact, while the coating absorbs the daily punishment. Unlike paints that chip or thin films that peel, advanced coatings bond tightly and cure into seamless membranes.

The value of these protective systems becomes clear in demanding environments. In warehouses, racks coated with resilient polymers resist damage from repeated forklift contact. On shipping docks, wooden supports treated with moisture-resistant coatings hold up under rain or salt spray. Across road and rail networks, coated surfaces prevent vibration damage from reaching the core material.

The role of polyurea in dunnage coatings

Among the materials available, polyurea has gained attention for its combination of strength and flexibility. Applied as a spray, it bonds instantly to the substrate and cures within seconds. Once in place, it forms a continuous membrane with no seams or overlaps. The absence of weak points means fewer opportunities for cracks or peeling.

Polyurea’s elasticity makes it particularly effective for dunnage applications. It stretches slightly under impact, absorbing force without breaking its bond. This flexibility allows it to endure repeated stress from shifting loads and handling equipment. At the same time, it resists ultraviolet degradation, water intrusion, and many industrial chemicals. These traits explain why industries have adopted polyurea dunnage coatings to extend the service life of their cargo systems.

Dunnage coatings in modern logistics

The adoption of coatings reflects a broader change in how companies view maintenance. Instead of treating equipment as disposable, operators now recognize the value of prevention. By applying dunnage coatings, they delay wear, reduce replacement cycles, and maintain consistent operations. The cost of coating is balanced by the savings in downtime and reduced risk of cargo damage.

This philosophy aligns with the growing demand for efficiency in global supply chains. Cargo moves farther and faster than ever before, and any failure has consequences that ripple across schedules. Protecting the equipment that stabilizes goods ensures that the chain remains intact from origin to destination.

Broader implications for cargo safety

The significance of protective systems extends beyond cost savings. Safe cargo handling depends on stable loads, and stable loads depend on dunnage that does not fail under stress. When a rack collapses or a support block breaks, the resulting damage can injure workers and damage or destroy products. Coatings help prevent these events by reinforcing surfaces and preserving structural integrity.

For this reason, organizations that focus on standards and safety have taken interest in promoting protective measures. The discussion of cargo protective coatings highlights how surface science supports both safety and efficiency. By preventing small surface failures from turning into large structural failures, coatings contribute to a safer working environment across warehouses, ports, and transport networks.

Looking ahead

The role of dunnage will only grow as transport volumes increase. Heavier loads, longer shipping distances, and more complex global networks will place greater stress on the systems that hold cargo steady. Coatings will continue to evolve, offering increased resistance to abrasion, enhanced chemical stability, and even added features such as anti-slip surfaces.

The path forward is clear. Protecting dunnage protects the cargo, and protecting the cargo protects the entire chain of commerce. Surface technology, once overlooked, now stands as a key element in ensuring goods move safely and efficiently.

Conclusion

Dunnage carries weight in more ways than one. It holds cargo in place, supports safe handling, and forms the foundation of reliable transport. But it cannot perform its role without protection. Coatings, and particularly polyurea systems, offer that protection by creating durable, flexible barriers against the daily stresses of logistics.

By investing in dunnage coatings, companies strengthen the unseen infrastructure that keeps global trade moving. They gain longer-lasting equipment, safer operations, and more stable supply chains. In a world that depends on reliable movement of goods, the surface strength of dunnage matters as much as the cargo itself.