INDEPENDENCE HAS NEVER BEEN EASIER

Municipalities, busy as they are, have often sought outside help to rehabilitate wastewater infrastructure and protect these systems against future wear. This is especially true for manholes, which dot the urban landscape right before our eyes and just below our feet, enabling essential services so that the rest of us don’t have to think twice when we turn on the tap or flush the toilet. Nobody can blame municipalities for deferring to specialized coatings experts, but relying on third-party contractors no longer delivers the same cost-efficiency or productivity. Today, municipalities can invest in in-house capabilities more easily than ever before, saving money, improving the speed and quality of their services, and gaining an unprecedented level of flexibility and stability by making the switch.

COST SAVING, PERFORMANCE-ENHANCING

Arguably the chief concern for any municipality is cost—how can they meet or exceed performance metrics while stretching their budget further? Well, by investing in the tools, materials, and training to equip municipal crews with coatings expertise, municipalities can achieve the same results that outside contractors previously delivered, but without having to pay a premium. Hiring third parties means paying extra for labor, material markups, and priority service, whereas taking control of manhole coatings eliminates these costs and lets municipalities manage application quality directly.

FASTER, EASIER, AND MORE RELIABLE

Cost considerations aside, the time required to address manhole rehabilitation and protection is another critical factor for municipalities. Thousands, even millions of people, rely on the services municipalities provide, including those that depend on safe and functional manholes, so municipalities must take swift action when manholes need repair, replacement, or protection. With in-house capabilities, municipal crews can determine exactly when treatment is necessary and how quickly to address the problem, without delays from contractor availability or a sluggish external crew. This also lets municipalities streamline the coatings process, making the planning and execution of manhole coating projects far simpler and significantly more reliable.

FLEXIBLE AND CUSTOMIZABLE

On top of cost, convenience, speed, and reliability (if that wasn’t already enough), municipalities can also benefit from investing in in-house manhole coating capabilities by gaining flexibility and customizability. Outside contractors may lack the tools, equipment, materials, or expertise to handle projects that require a specific approach for a unique municipality, and they set their own service standards and methods. Instead, municipalities can take charge of manhole rehabilitation with far greater flexibility, adapting to their unique circumstances and eliminating reliance on outside partners.

IN SUMMARY

There’s no doubt that with the right partner, under the right circumstances, third parties can deliver high-quality manhole coating services to municipalities. However, if municipalities want long-term cost savings, faster project completions, and improved flexibility and stability today, tomorrow, and for years to come, they should invest in in-house manhole coating capabilities. As with so many other coating applications, polyurea leads the way here, too. It works for both traditional manhole replacement and trenchless manhole rehabilitation, meeting all the essential criteria for protecting wastewater infrastructure.

FREQUENTLY ASKED QUESTIONS

Why Should Municipalities Use Polyurea For Manhole Rehabilitation?

Polyurea meets all the criteria for high-quality manhole rehabilitation. It offers exceptional durability and resists corrosion from gases like hydrogen sulfide, which constantly surround manholes. It’s also watertight yet flexible, blocking water intrusion while shifting with manholes and surrounding surfaces.

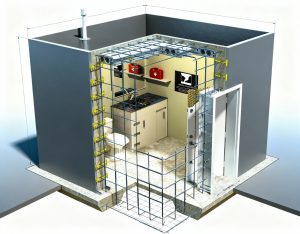

What Equipment Do Municipalities Need To Perform Manhole Rehabilitation In-House?

No single approach equips municipalities with everything they need to handle their own manhole rehabilitation projects. Their selection of tools, materials, and training depends on their unique needs, but in general, they need high-pressure spray equipment, high-performance coatings like polyurea, and surface cleaners and modifiers.

Is Manhole Rehabilitation Better Than Manhole Replacement?

Choosing to rehabilitate rather than replace manholes can save municipalities a significant amount of money—not to mention time, frustration, and operability. Trenchless manhole rehabilitation, the process of restoring manholes with coatings like polyurea or polyurethane, mostly or entirely eliminates the need for excavations, which is the largest source of financial and productivity loss.